Why Spider Silk is Hard to Spin: New Physics of Biopolymer Flows

Monica Cooney

Oct 16, 2025

For many years polymer researchers have sought to recreate naturally occurring biopolymers, like spider silk, that are both strong and biodegradable. While progress has been made in creating synthetic versions of these materials, researchers have struggled to replicate the processes bugs use to assemble and spin biopolymers into strong fibers and materials.

A recent study from the department of materials science and engineering at Carnegie Mellon uses advanced molecular simulations to explore why silks are so difficult to process into materials. The study by Ph.D. candidate Songyue Liu and assistant professor Thomas O’Connor shows that associative biopolymers display new physical behaviors during deformation that are not present in synthetic polymers or captured by current models of polymer processing.

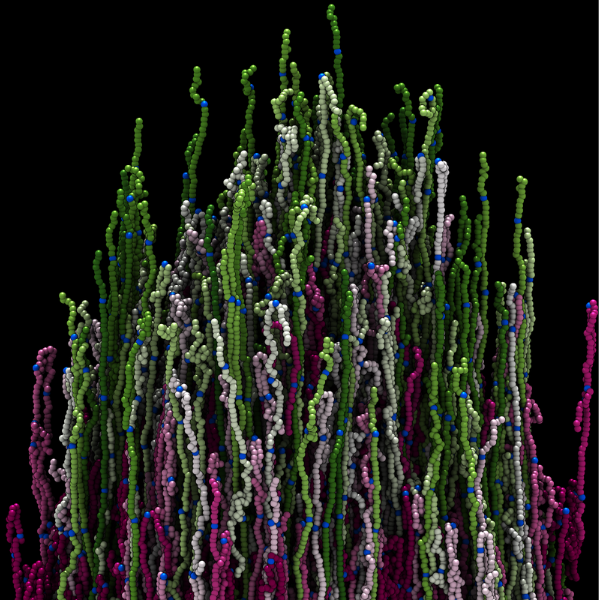

Molecular simulations predict how associative polymers elongate into oriented structures during fiber formation.

“Most man-made polymers are processed in large, industrial facilities and require high power machinery and toxic organic solvents, but bugs routinely spin high-performance polymer materials in your backyard,” said O’Connor. “These creatures have mastered both the chemical formulation and the processing of these biodegradable and biocompatible plastics. Our work is trying to understand not just the materials, but also the processes that nature has developed to efficiently create biosynthetic materials.”

Current commercial plastics like polyethylene and polystyrene are derived from oil and are difficult to recycle. In contrast, spiders naturally produce strong silks, but can also digest and recreate these polymers on demand. If this process could be mimicked in man made materials, it would be widely beneficial and enable processing with less energy, fewer chemical additives, and less waste. The challenge has been actually spinning biopolymers into useful fibers, which requires accurate models of their viscoelastic flow behavior. Polymer scientists have very accurate models of synthetic polymers, but these models fail when applied to flowing silks.

“A biodegradable polymer isn’t useful if we do not know how to process it into something practical in the first place,” said O’Connor. “Our work shows that we cannot just assume biopolymers behave like the synthetic plastics we are familiar with.”

Our work shows that we cannot just assume biopolymers behave like the synthetic plastics we are familiar with.

Thomas O'Connor, Assistant Professor, Materials Science and Engineering

The study uses molecular dynamics simulations to test predictions about how chemically associative polymers (like silk proteins) behave as they are stretched into fibers. Associative polymers have the ability to reversibly bind their chains to each other, which can make a material tougher or enable it to exhibit self-healing. However, Liu and O’Connor’s study revealed that these intermolecular associations make chains undergo complex tumbling motion when they try to stretch out. They showed that this chain tumbling process causes the unusual viscoelastic flow behaviors observed in experiments on associative polymers.

“We build simulations that bridge the gap between the hypotheses of molecular-scale theories and the mechanical experiments that are possible in the lab,” he noted. “We can simulate the deformation process and identify the molecular mechanisms mediating a material's mechanical behavior.”

As this research informs future experimental studies, O’Connor is hopeful that these simulations can aid efforts to make better biomaterials, but also help us better appreciate nature's first and best polymer engineers - the bugs.