Making magnetic connections

Monica Cooney

Mar 19, 2024

Johnson delivers a recent graduate student seminar at CMU.

Magnets are fundamental to billions of devices - from phones to cars to power tools. The materials that power these devices face numerous challenges related to sustainability, supply chain, and cost. Materials science and engineering alumnus Frank Johnson (B.S. '96, Ph.D. '03) is part of a team that is creating an environmentally friendly alternative that offers higher magnetization without the supply chain challenges.

Niron Magnetics is using patented manufacturing techniques to precisely control and manipulate the crystal structure of iron nitride in order to produce high-strength magnets that are free of rare-earth materials. Johnson joined Niron in 2018 as VP of R&D and Senior Metallurgist, and as the company has expanded, he has transitioned into the role of Chief Technology Officer.

While working at a small start-up after his previous experience at General Electric was somewhat daunting, the skills that he had developed as a student prepared him for the work that lay before him.

“The interdisciplinary nature of the work I did at CMU was fundamental to my career path,” said Johnson. “The challenges we face are rarely limited to the materials themselves. Gaining knowledge that crosses many aspects of operations, from intellectual property to environmental factors, was instilled during my time as a student.”

The interdisciplinary nature of the work I did at CMU was fundamental to my career path.

Frank Johnson, B.S. '96, Ph.D. '03, CTO, Niron Magnetics

One could say Johnson’s connection to CMU was “magnetic” from the beginning of his academic career.

As a high school student, he attended a pre-college program that gave him a taste for life on a college campus. When asked about what stuck out from that experience, he recalls that all of the residence halls had network outlets - a progressive technology at the time. Because his father worked in the specialty steel industry, he was exposed to the study of metallurgy at an early age, which furthered his interest in studying materials science.

The timing of his introduction to professor Mike McHenry was fortuitous, due to the recent discovery of “buckyballs,” or buckminsterfullerene, a previously unknown allotrope of carbon consisting of 60 carbon atoms linked in the form of a soccer ball. This discovery had spurred multidisciplinary research projects, including the CMU Buckyball Project, a project that involved 20-30 undergraduates over the course of several years in the 1990s. It was supervised by McHenry and physics professor Sara Majetich, and Johnson was enthusiastic to participate.

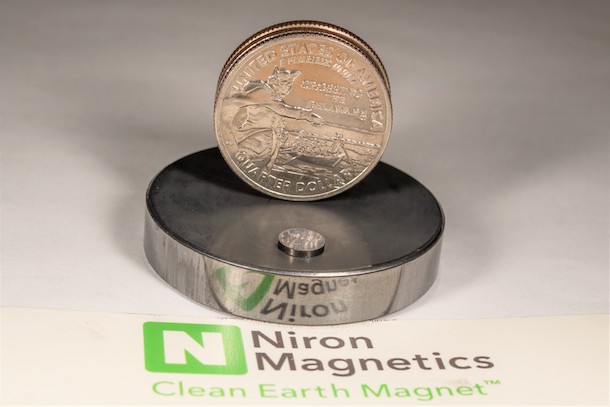

Source: Niron Magnetics

A magnet created by Niron with a quarter for scale.

“Opportunities such as this for an undergraduate were still fairly novel,” recalls Johnson. “Working on this project laid the groundwork for my future research experiences.”

After pursuing a master’s degree at Massachusetts Institute of Technology, Johnson was drawn back to CMU for his doctoral degree. He had kept in contact with Dr. McHenry, and saw abundant opportunities to study nanomaterials arising from new facilities and equipment, such as the Materials Characterization Facility (MCF) in Roberts Hall.

Ultimately, Johnson’s doctoral work enabled his path to working at Niron Magnetics, as he gained experience in their processing methods through his thesis work. The company has grown from a handful of employees to working with more than 70 individuals, as well as partners across government, academia, and industry. The skills acquired as a student continue to serve Johnson as a leader at Niron.

“It’s extremely valuable to have the depth of connections created at CMU,” says Johnson. “The disciplines and coursework gave me the foundation to understand what is possible.”