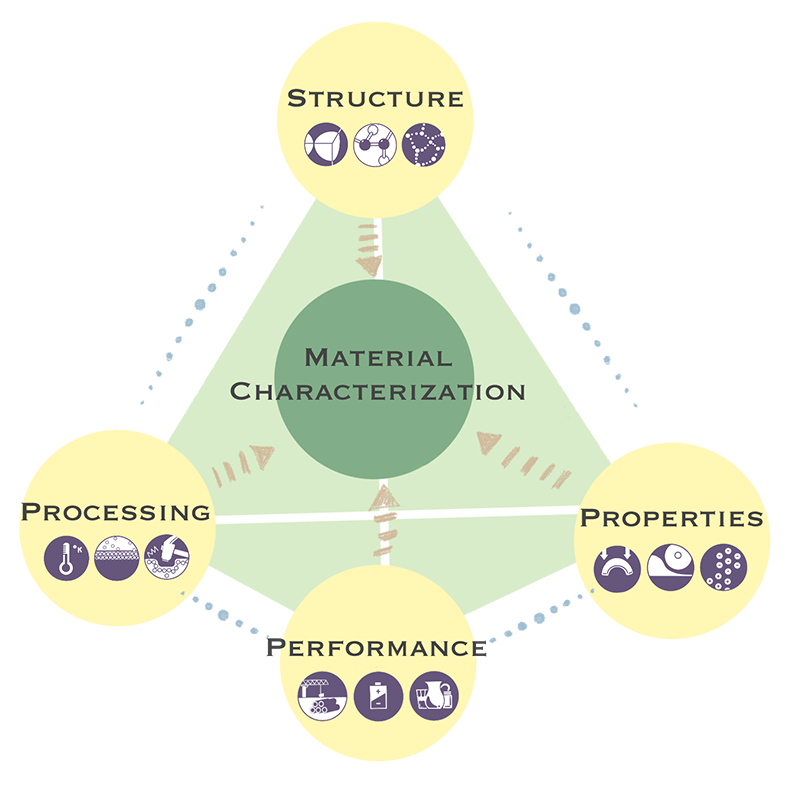

What is Materials Science and Engineering?

Materials Science and Engineering (MSE) applies the tools of basic and applied sciences and engineering to the manufacturing and application of materials and devices. Every technology, from the first wheel of the past to the first 3D printed heart of the future, depends on materials development and innovation.