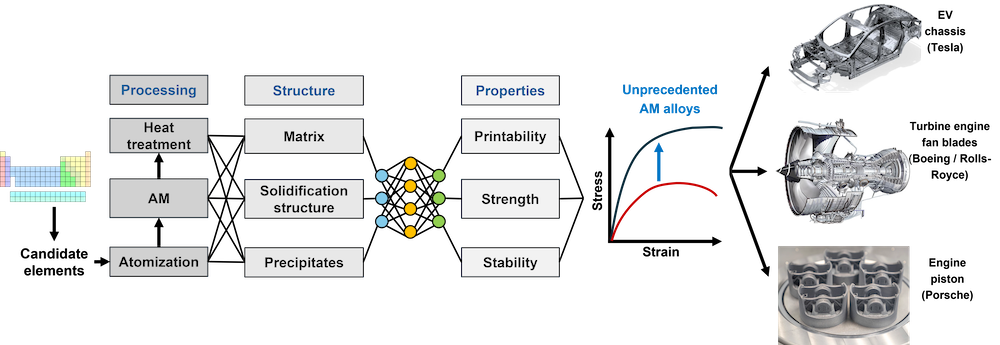

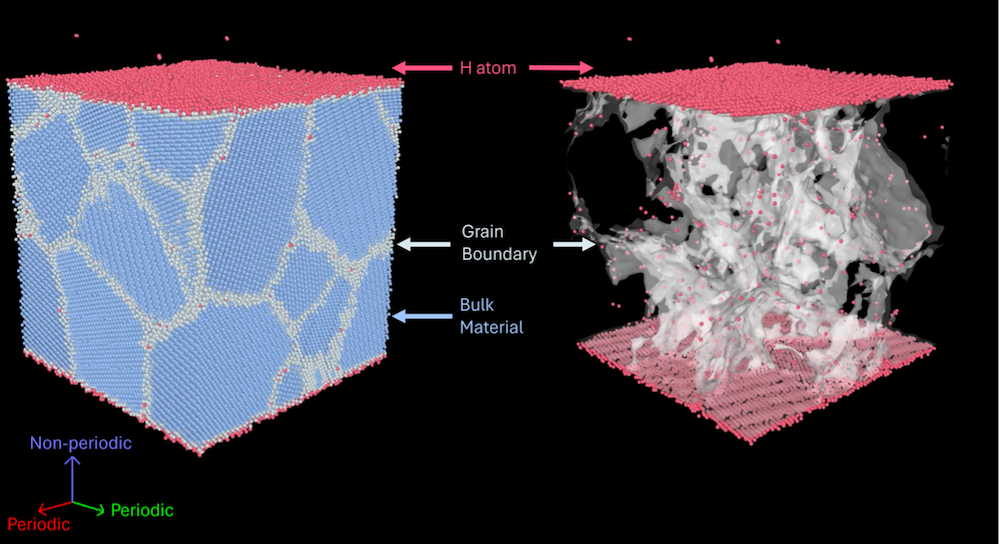

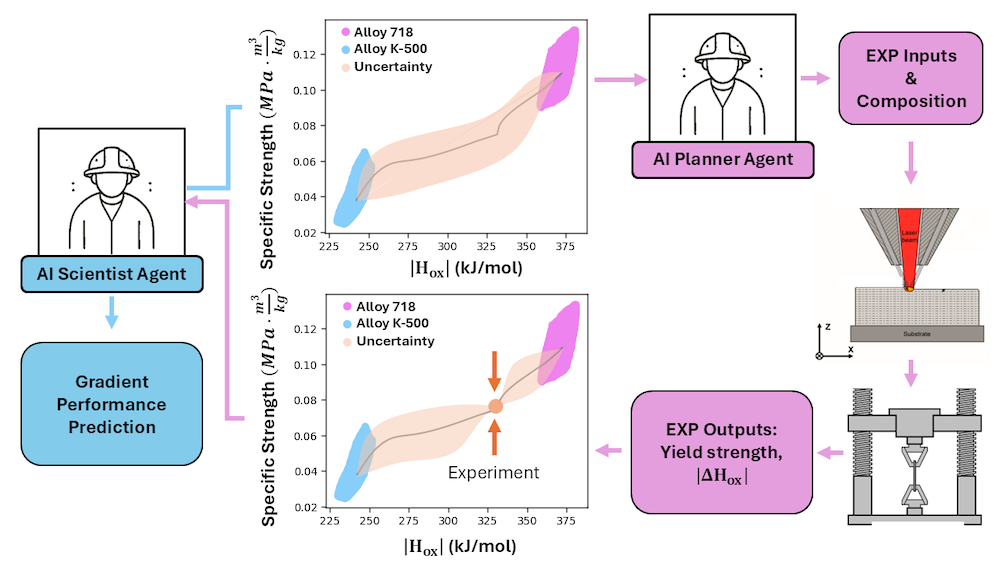

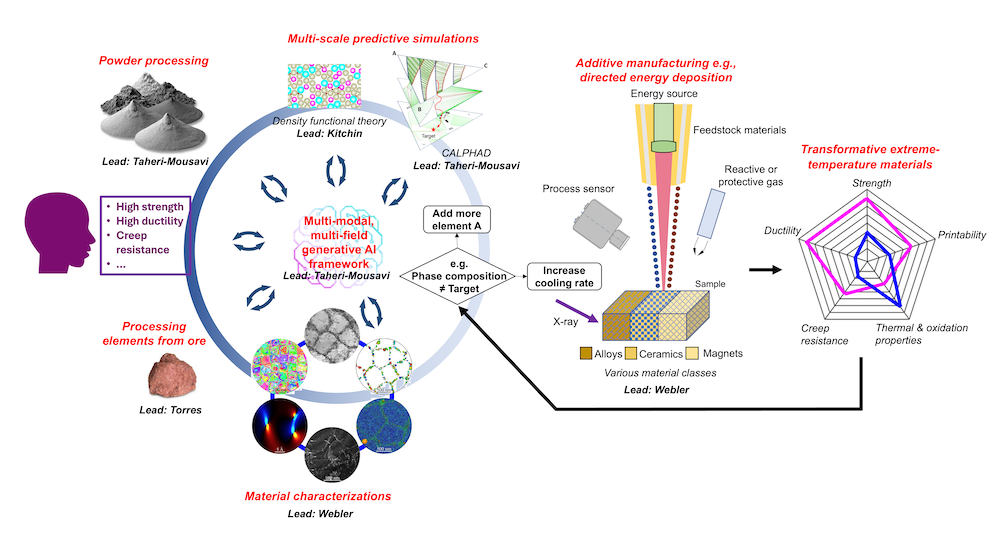

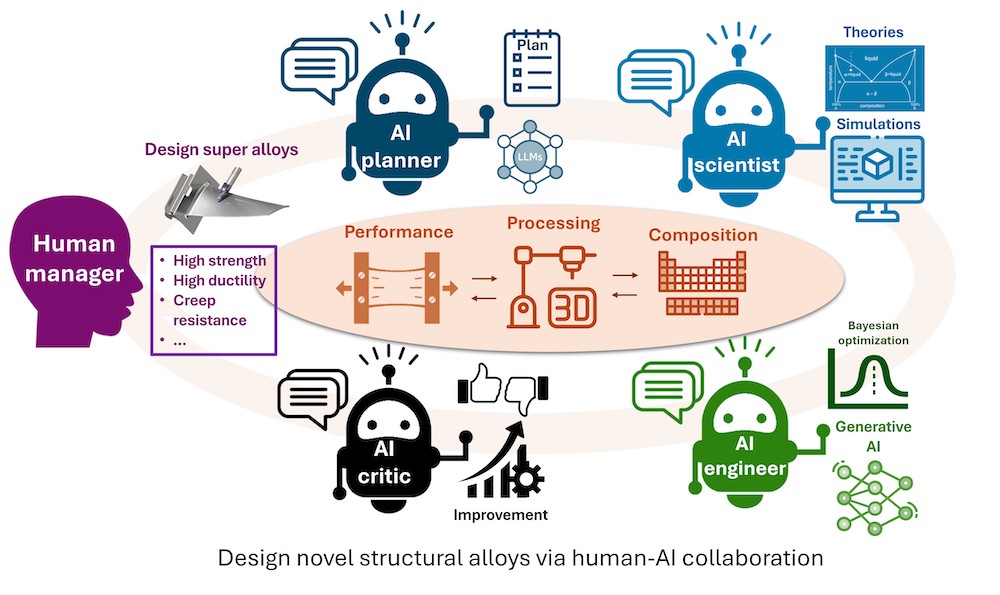

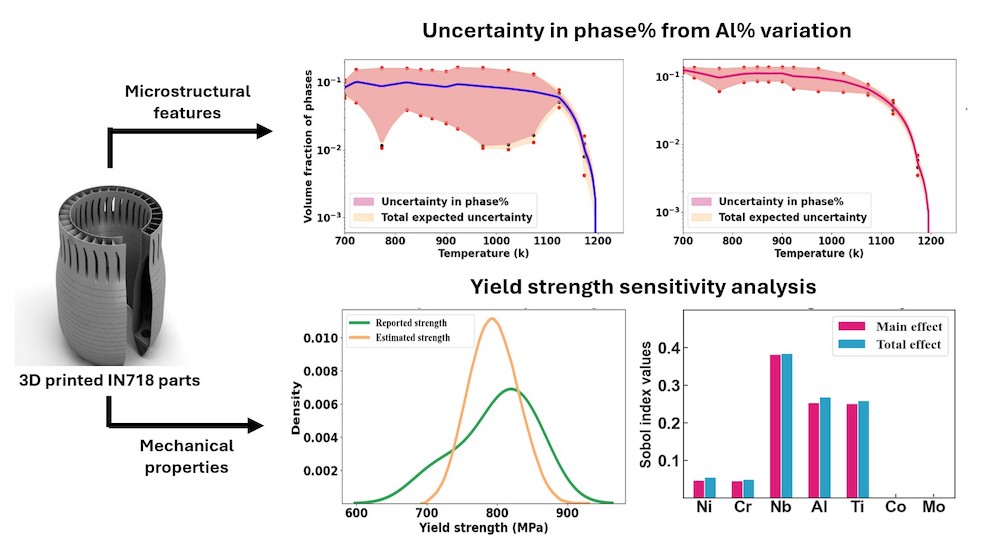

Structural alloys play pivotal roles in various engineering applications. And the pursuit of ever stronger, tougher and better alloys often requires effective collaboration between different experts in performing processing, simulations, and experiments and also integration of their various information flows. To handle this fast-growing knowledge base, navigate through the broad design space, and achieve enhanced designs, we invite AI-enabled tools and players into the game and develop the human-AI collaborations for next-generation alloy design. We actively explore language-based models (e.g., AlloyGPT) for integrating knowledge of various formats (figure, text, video, audio, etc.), develop smart agents which can apply modeling/experimental tools (e.g., AlloyGen), and organize autopilot AI teams to discover novel alloy physics and design promising alloy candidates. We expect our efforts will deepen fundamental understanding of structural alloy systems, lead to novel workflows for material discovery and contribute to a sustainable future.